BICOX AUTOMATIC ELECTRIC CUTTING PRESS

Data sheet

| Max cutting force | 30 tons |

| Arm dimensions | 400 mm x 400 mm ( hammer 400 mm or hammer 500 mm ) |

| Table dimensions | 2180 mm x600 mm |

| Pump motor | 15 kW |

| Dimensions | 3025 mm x 2080 mm x 2030 mm |

| Weight | 5800 kg |

| Control DC | DC : 24 V |

| Pneumatic pressure | 5 - 8 bar |

| Continuously adjustable stroke | 5-100 mm |

| Maximum distance of table from stamp | 100 mm ( 200 mm without equipment ) |

| Drive | Electrical |

| Min/ max. power | 0,5 / 15 kW |

| Voltage | 3x400 V; 50 Hz |

More info

BICOX electric cutting press

The BICOX machine is a state-of-the-art programmable cutting press used to cut all types of soft materials (up to medium hard materials) using cutting dies. The cutting press can be used in many industry branches, e.g., automotive industry, printing industry, packaging, production of seals, plastic processing, sheeting, paper industry and many others.

Advantages of the BICOX machine:

-

high cutting force: 30 tonnes (up to 165 tonnes)

-

intuitive programming using a touch panel

-

high cutting precision: 0.02 mm (play to be agreed)

-

repetitive precise cycles

-

fast operation

-

low material use

-

very quiet operation (with direct drive)

-

low power draw

-

no hydraulic fluid

-

margin between the workpieces < 1 mm

The innovative design using the technologies described below enabled the development of the state-of-the-art machine and achievement of parameters that could not be attained by cutting presses of the old type, i.e., hydraulic cutting presses.

For comparison, in hydraulic cutting presses, the die is pressed against the materials by cylinders, which do not enable accurate positioning due to the medium they use (among other things). All types of mechanical solutions improving the operating parameters required the use of accurate and very expensive components, and the desired effect was achieved only in the initial period of use and quickly deteriorated as those components wore out.

In the BICOX travelling head cutting press, the required cutting stroke is made up of a sum of the thickness of the material to be cut and the required distance between the cutting knife and the material. It is not recommended to use different knife heights due to the possibility of incorrect setting, but it is possible. If knifes with a different height (e.g.: 24 and 32 mm) are used, it should be ensured that they can be easily and intuitively identified, or instrumentation should be used to eliminate the risk of errors when the settings are changed. Minor corrections of knife height due to knife wear can be introduced by the authorised personnel.

The BICOX machine has been provided with many state-of-the-art solutions and functions, e.g.:

-

all drives are servomotors

-

head travel performed by 2 ball screws

-

material is fed using linear guides and a ball screw

-

ABS absolute measurement system

-

RTC real-time operation

-

supports barcode scanners

-

automatic report generation

-

LAN data exchange and diagnostics

-

Ethernet/IP (SCADA) data exchange

-

supports advanced systems (measurements, corrections and detection of deficiencies)

-

suitable for direct connection of robots, e.g., packing or sorting robots

as a result of which the machine is highly versatile and functional and can be used for a variety of purposes.

The high quality of the components and the applied technology considerably increased precision, reducing the wear of tools and consumable use.

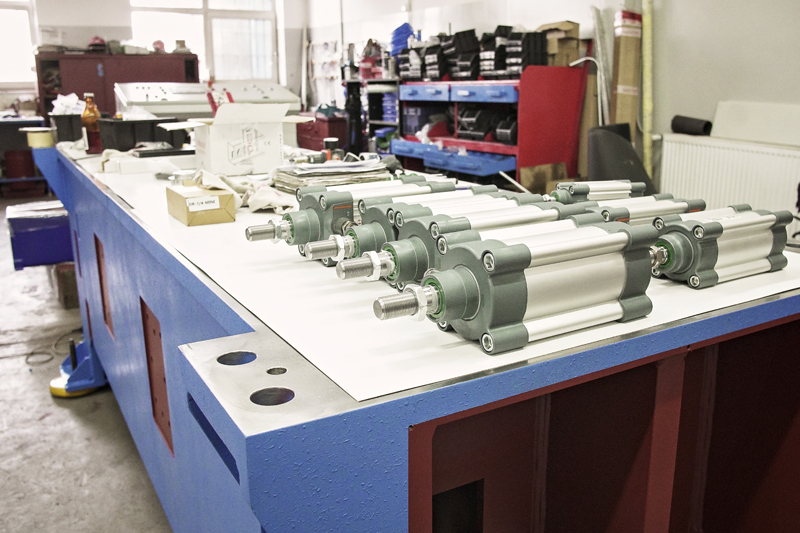

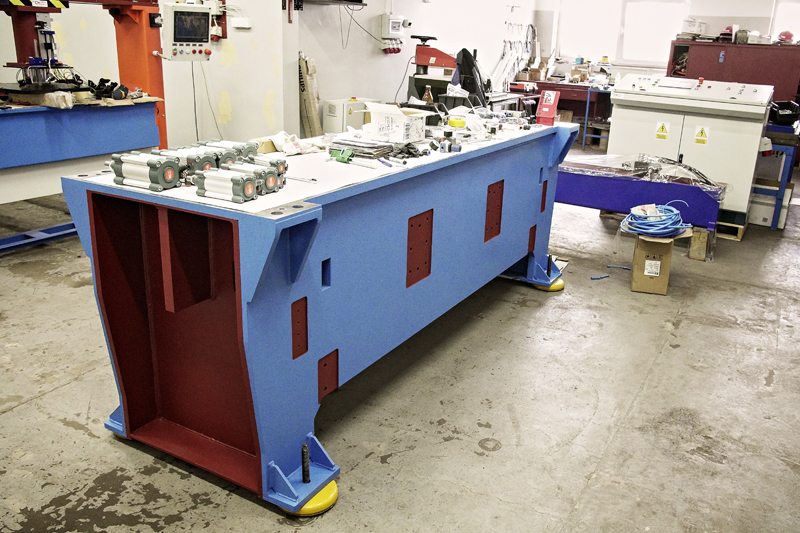

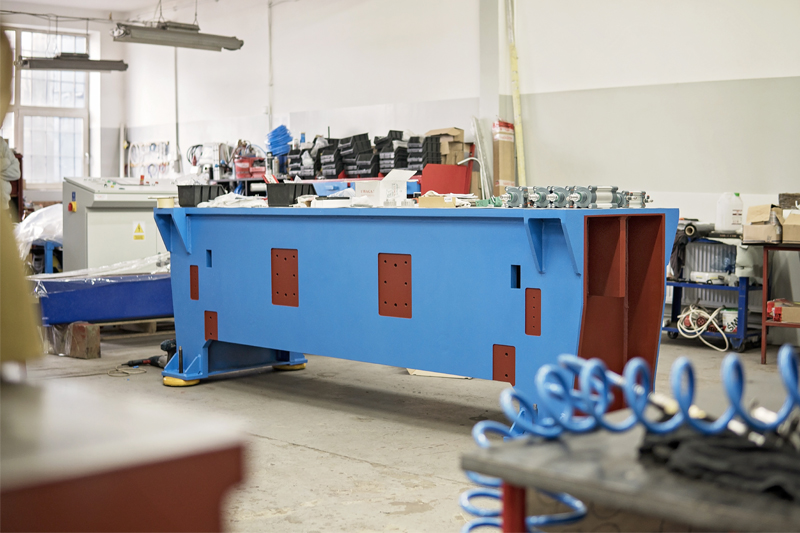

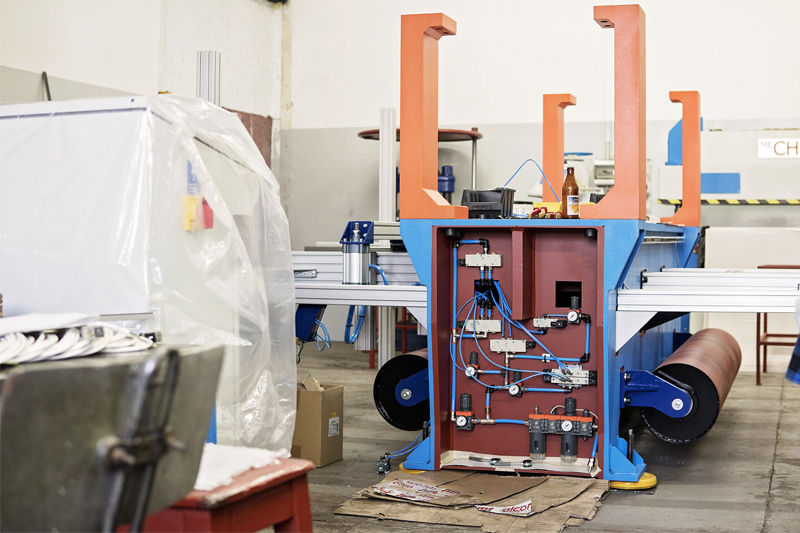

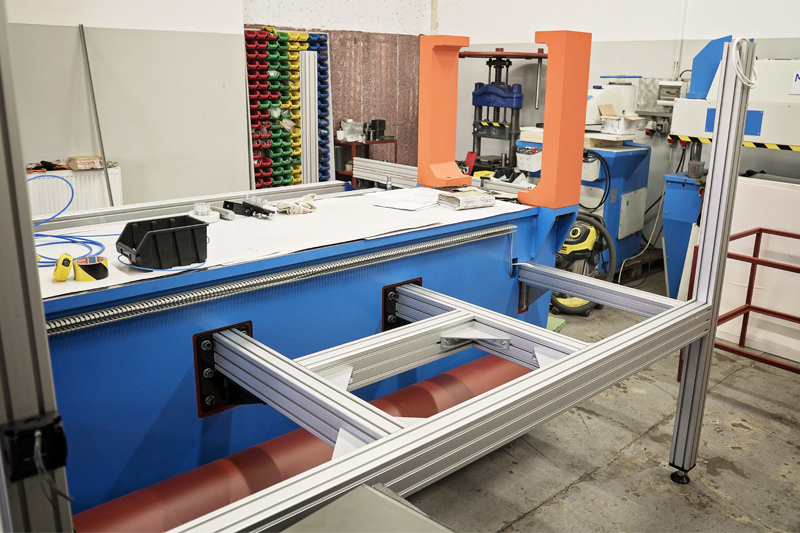

MACHINE UNDER CONSTRUCTION

|

|

|

|

|

|

|

|

|

READY MACHINE

|

MACHINE WORK

10 other products in the same category: