MSP 2000 Precision Bridge Cutter with Dropping Hammer

specification

| Maximum cutting force | 100 ton |

| Table dimensions | 2000 mm x 1050 mm |

| Libra | 7500 kg |

| Cutting accuracy | 0,025 |

| Continuous adjustable cutting stroke | 10-275 (option 10-475) |

| Max. Distance from table to hammer | 300 mm (option 500, 750) |

| Drive: | Electric |

| Min / max power: | 3/ 15 kW |

| Rotation speed: | 3080/ 2000 obr/ min |

| Tension: | 3x380V 50 Hz |

| Drive type: | Servo |

| Control type:: | Electro-pneumatic |

More Information

The MSP 2000 machine is a modern, precise cutter designed for cutting various soft to medium-hard materials using dies. This cutter can be applied in numerous industries such as automotive, printing, packaging, gasket production, plastics processing, film, paper, and many others.

Its innovative construction, utilizing the technologies described below, has allowed the development of a modern machine with previously unattainable parameters for older types of cutters, such as hydraulic cutters. In hydraulic cutters, the die pressure on the material is achieved by actuators, which, among other reasons, due to the medium used, do not allow for precise positioning. Operating mechanical devices requires a considerable financial outlay. All kinds of mechanical solutions aimed at improving work parameters required the use of precise and very expensive components, and the desired effect was achievable only at the beginning of use and quickly deteriorated with the wear of these components.

MSP 2000 Performance:

- Cutting speed

- 4-detail die

- 6 layers cut at 2 mm each

- Upper position 150 mm, lower position 52 mm

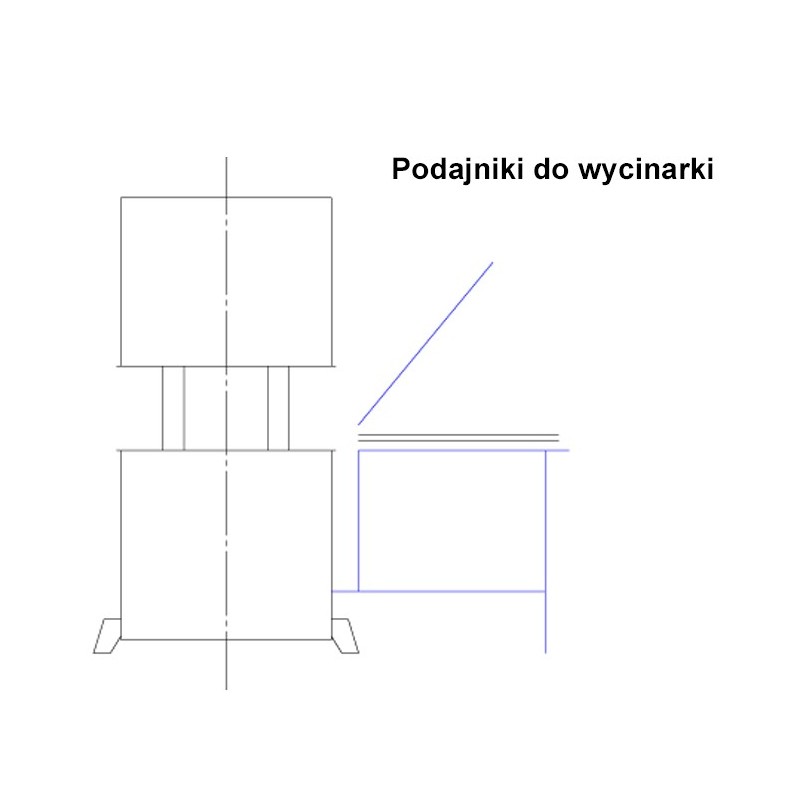

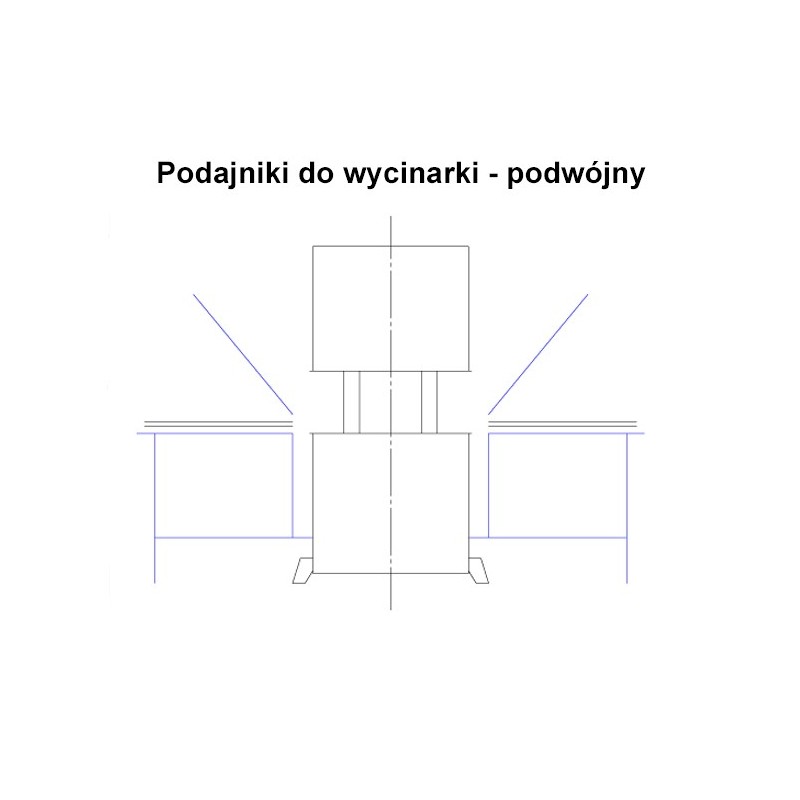

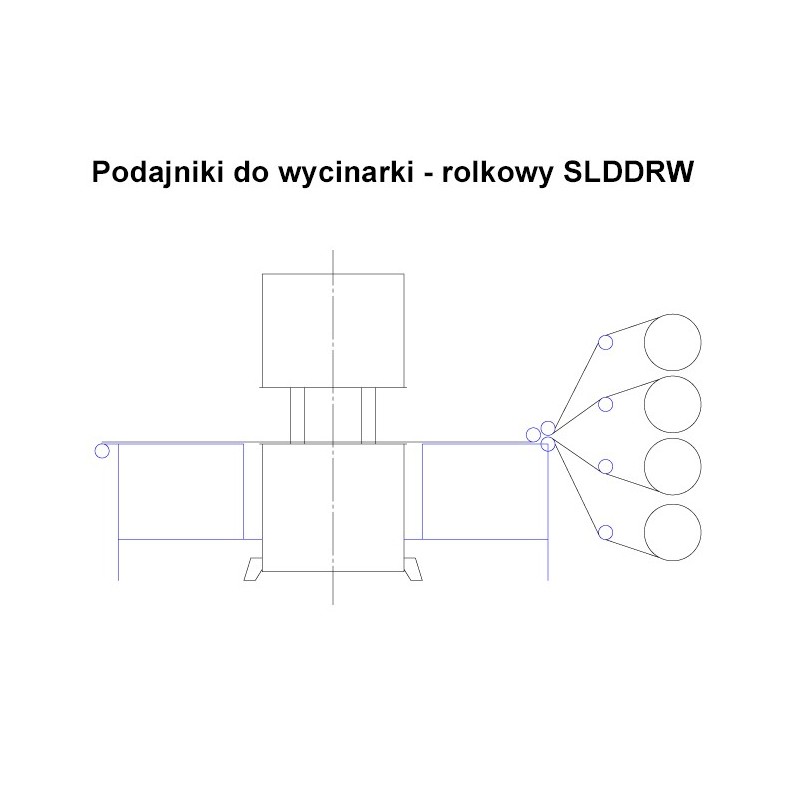

- Manually operated automatic feeder

- Number of details per shift (7.5 hours) – 21,600

Advantages of the cutter:

- High cutting force up to 100 tons

- High cutting precision of 0.01 mm

- Repeatability of precise cycles

- High work speed

In hydraulic cutters, the die pressure on the material is achieved by actuators, which, among other reasons, due to the medium used, do not allow for precise positioning. Due to the medium used, they do not allow for accurate positioning. All kinds of mechanical solutions aimed at improving work parameters required the use of precise and very expensive components, and the desired effect was achievable only at the beginning of use and quickly deteriorated with the wear of these components.

Deviation requires frequent parameter corrections. The new method of forcing the hammer’s working movement in our machine results in increased work efficiency and allows for convenient, quiet execution of technological operations. High-quality components and technology significantly increase accuracy, thereby reducing tool and consumable material consumption. The machine is suitable for cutting large-format elements from sheet material or rolls, from one or more layers.

Years of experience and knowledge in the production and repairs of cutters have allowed us to produce a machine with outstanding parameters, unique construction, and an attractive price.

The MSP 2000 machine also performs well in continuous (three-shift) operation as a reliable, fast, and highly accurate machine. MSP 2000 allows for automatic cutting with scoring (kiss cutting).

Machines

Machines  Service

Service  Screws

Screws  Spare Parts for Rail Vehicles

Spare Parts for Rail Vehicles