Automatic Electric Die Cutter BICOX

specification

| Maximum cutting force | 30 tons |

| Hammer dimensions | 500 mm x 500 mm (max 700 mm x 700 mm) |

| Table dimensions | 2400 mm x 750 mm |

| Engine power | 18,5 kW |

| Dimensions | 3800 mm x 2900 mm x 2800 mm |

| Libra | 7500 kg |

| DC Control | DC : 24 V |

| Pneumatic supply | 5 to 8 bar |

| Continuous adjustable cutting stroke | 5-100 mm |

| Max. Distance from table to hammer | 100 mm (200 mm without tooling) |

| Drive: | Electric drive |

| Min / max power: | 0,5 / 18 kW |

| Electric supply: | 3 x 400 V; 50 Hz |

More Information

Automatic electric die cutter BICOX from the Polish manufacturer “MECHANIK S” from Chełmek.

The BICOX die cutter was entirely designed and manufactured by “MECHANIK S” company.

In response to customer needs, we have designed and built an electric machine from scratch with very good parameters.

We had the idea of creating such a machine for a long time, and after many months of workin 2015, we released our first machine on the market.

We designed and manufactured this die cutter with the idea of its application in many industries, including:

- automotive

- printing

- packaging

- gasket production

- plastics processing

- paper and foil industries

and many others

Basic information about the electric die cutter BICOX:

The machine we designed is a guarantee of precision and exceptional ease of use. It offers significantly greater accuracy than hydraulic die cutters, where the work is done by actuators that do not allow achieving user-defined positions. Choosing electric solutions is a cheap and effective way to achieve the highest quality results of the production plan.

For comparison, in hydraulic die cutters, pressing the die into the material is done by actuators, which, among other things, due to the medium used, do not allow for precise positioning. Operating mechanical devices requires a considerable financial outlay.

To maintain the precise parameters of machines of this type, regular replacement of expensive components is necessary. That is why we designed an electric die cutter that, using technology, maintains exceptional precision throughout its entire service life. That is why we designed an electric die cutter that, using technology, maintains exceptional precision throughout its entire service life.

In the BICOX machine, we have applied many modern solutions and functions such as:

- all servo drives

- hammer movement carried out by 2 ball screws

- material feeding done by linear guides and ball screw

- absolute ABS measurement system

- real-time RTC operation

- cooperation with barcode reader

- automatic report generation

- possibility of LAN diagnostics and data exchange

- possibility of EtherNet / IP data exchange (SCADA)

- support for advanced systems (measurements, corrections, and defect detection)

- possibility of direct connection of robots, e.g., packing or sorting robots

Thanks to this, we have achieved extraordinary possibilities and functionality that can be used in many ways.

BICOX is the most technologically advanced electric die cutter, which eliminates any user concerns about additional expenditure. Solutions of this type effectively reduce operating costs while maintaining maximum work accuracy.

Advantages of the BICOX machine:

- high cutting force of 30 tons (up to 165 tons)

- intuitive programming with a touch panel

- high cutting precision of 0.02 mm (tolerance to be agreed)

- repeatability of precise cycles

- work speed

- low consumption of consumable materials

- very quiet operation (with direct drive)

- low power consumption

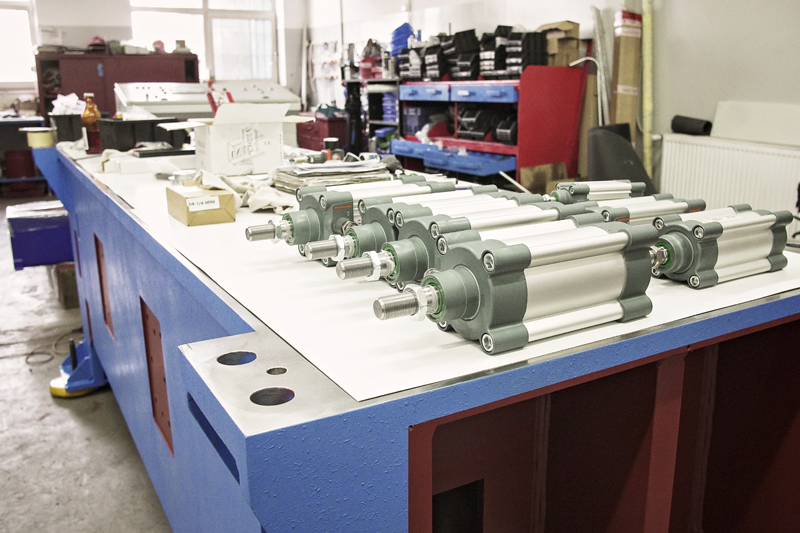

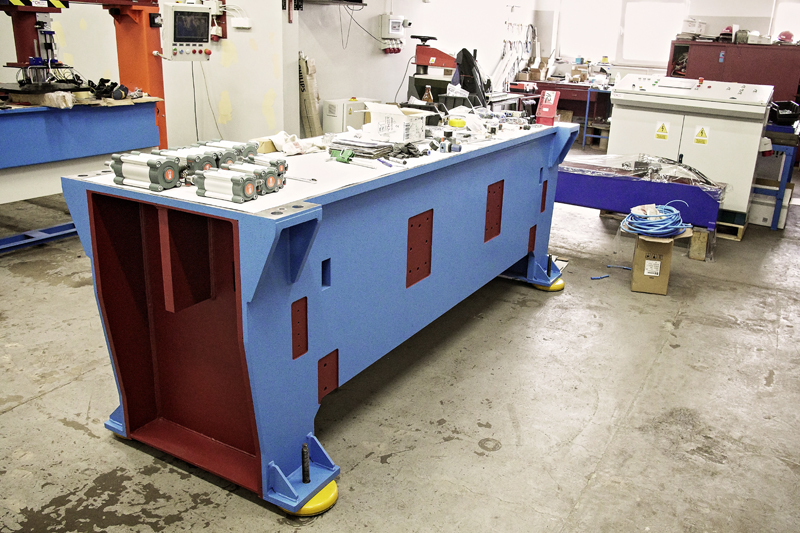

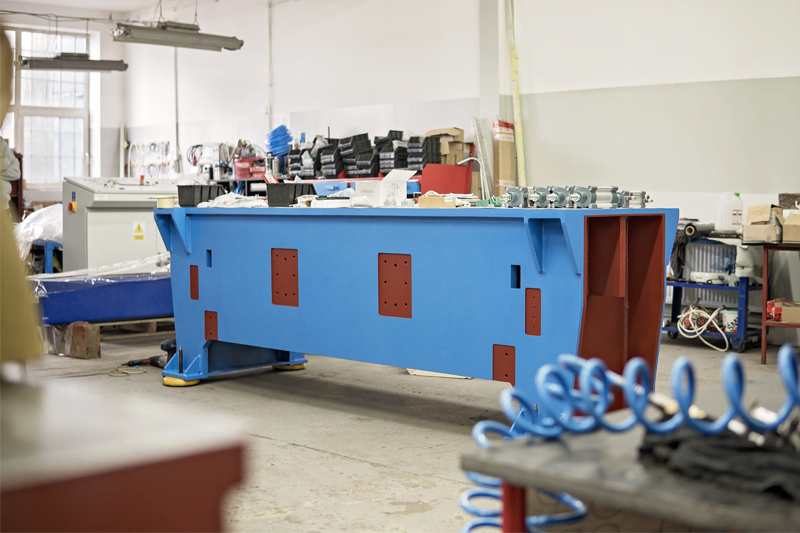

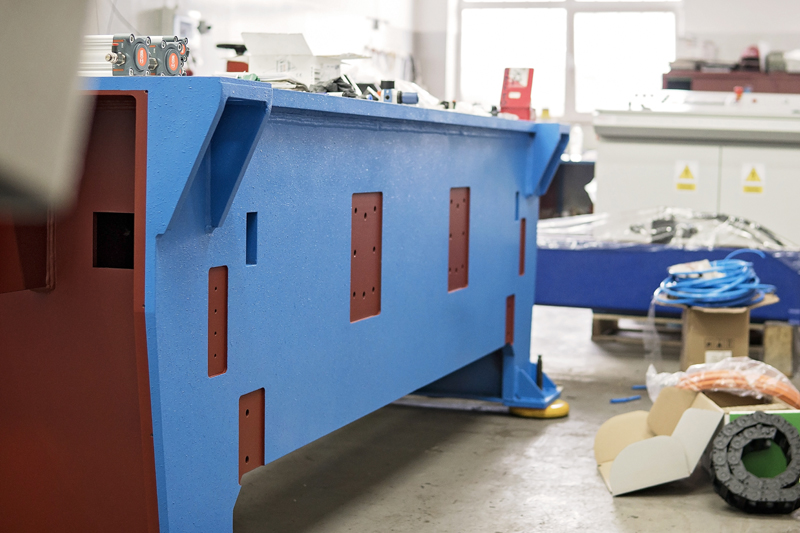

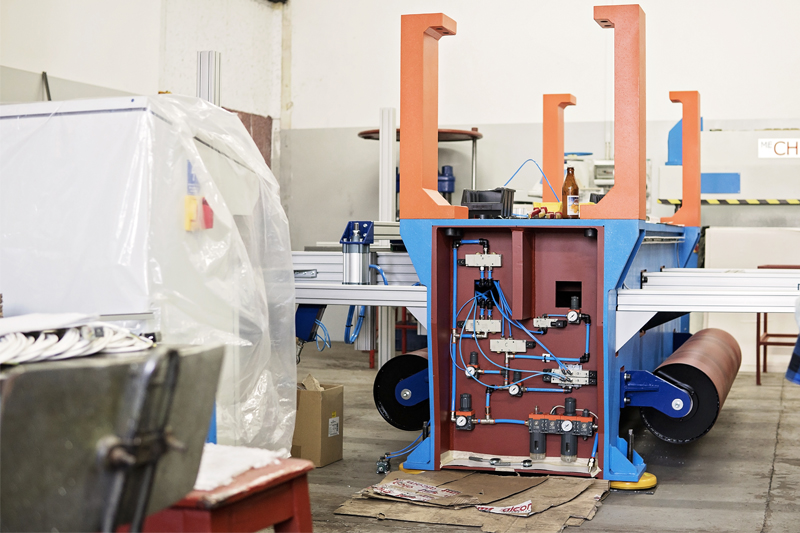

Machine under construction:

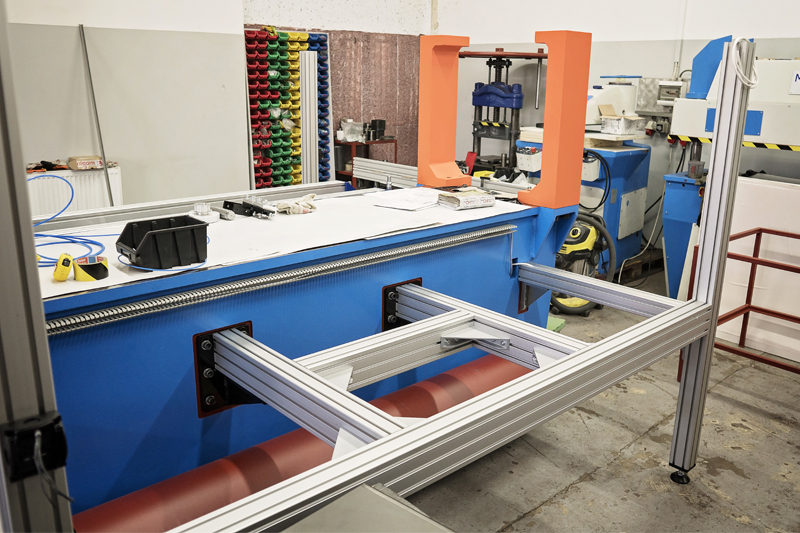

The finished machine:

Machines

Machines  Service

Service  Screws

Screws  Spare Parts for Rail Vehicles

Spare Parts for Rail Vehicles